In relation to shielding a building from water damage, g.i flashing plays a completely essential role. It’s miles a small creation aspect, but its impact at the sturdiness of roofs and walls is massive. Whether or not you are building a new residence or repairing an vintage roof, understanding flashing can prevent from luxurious repairs inside the destiny.

In this special manual, we are able to provide an explanation for what G.I flashing is, why it’s miles used, its kinds, sizes, charges, installation steps, and much extra. This newsletter is written in easy language so that house owners, developers, and beginners can without problems recognize it.

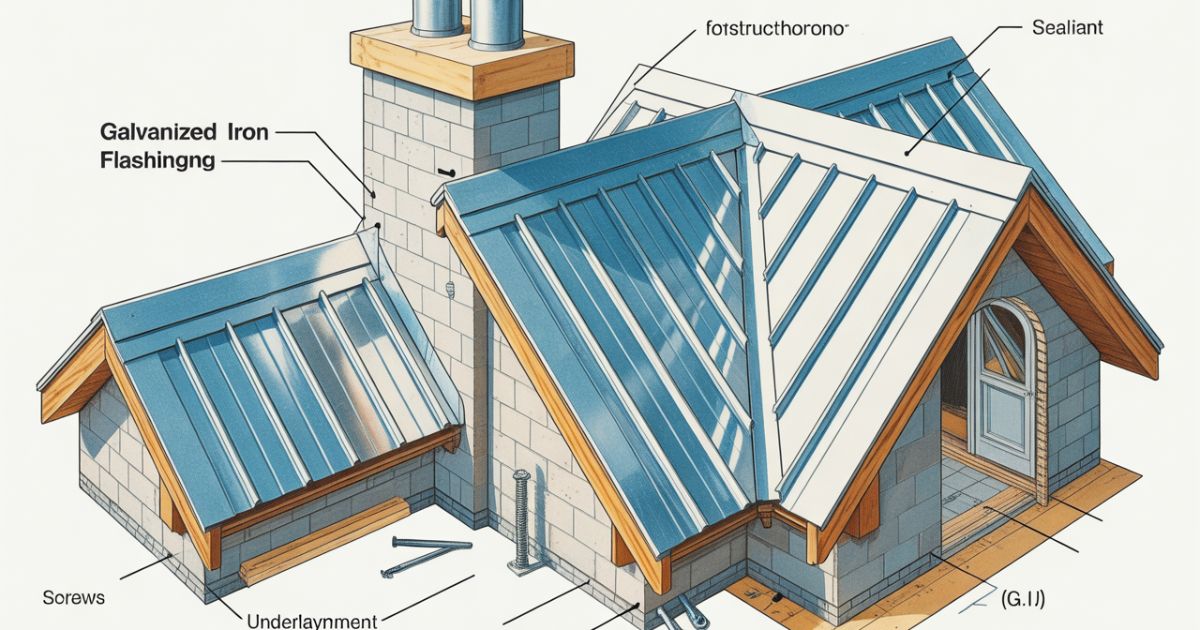

What is G.I Flashing?

G.I flashing refers to galvanized iron sheets used to save you water from getting into joints and gaps in a constructing. Those sheets are coated with zinc to defend them from rust and corrosion.

Flashing is normally established at:

- Roof edges

- Wall joints

- Chimneys

- Home windows and doors

- Valleys and corners

With the aid of directing water faraway from inclined regions, flashing facilitates maintain the energy and existence of the shape.

Why G.I Flashing Is crucial in Construction

Water leakage is certainly one of the most important motives for building damage. Without right flashing, rainwater can seep into walls and roofs, inflicting mold, cracks, and rust.

Key Advantages of the Usage of G.I Flashing

- Prevents water leakage

- Protects roofs and partitions

- Will increase the lifestyles of the structure

- Resists corrosion due to zinc coating

- Low-cost compared to different materials

- Smooth to reduce, bend, and deploy

Because of these advantages, galvanized flashing is extensively used in residential and business homes.

Common Programs of G.I Flashing

G.I flashing is versatile and can be used in lots of areas of construction.

Roof Programs

- Roof edges

- Valleys

- Round chimneys

- Skylight safety

Wall and Structural Uses

- Wall-to-roof joints

- Window and door frames

- Enlargement joints

These packages make it a crucial part of roof flashing structures.

Varieties of G.I Flashing

One of a kind construction desires require distinctive flashing designs. Beneath are the maximum commonplace kinds.

1. G.I Flashing Sheet

These are flat sheets reduce and bent consistent with the requirement. They’re normally used for custom installations.

2. Galvanized Flashing Roll

This kind is available in rolls, making it smooth to cover long sections without joints.

Exceptional for:

- Roof valleys

- Lengthy edges

- Non-stop surfaces

3. Metal Flashing

Steel flashing provides extra power and is appropriate for regions uncovered to heavy climate conditions.

G.I Flashing Sizes and Thickness

Choosing the proper length and thickness is essential for overall performance and sturdiness.

Not Unusual G.I Flashing Sizes

| Width (mm) | Period (mm) | Commonplace Use |

|---|---|---|

| 150 mm | 2400 mm | Roof edges |

| 200 mm | 2400 mm | Wall joints |

| 300 mm | 2400 mm | Valleys |

| Custom sizes | As required | Special areas |

Thickness Options

- 0.30 mm – Mild residential use

- 0.40 mm – Wellknown domestic construction

- 0.50 mm – Industrial homes

Thicker flashing offers better durability however may cost more.

G.I Flashing Charge Overview

The price of G.I flashing depends on thickness, size, and marketplace place.

Common G.I Flashing Rate Variety

| Thickness | Approximate charge (in step with sq. ft.) |

|---|---|

| 0.30 mm | Low value |

| 0.40 mm | Medium variety |

| 0.50 mm | Higher price |

Expenses may additionally range depending on logo, zinc coating exceptional, and dealer. Shopping for in bulk frequently reduces fee.

G.I Flashing vs Different Flashing Substances

Underneath is a comparison to help you pick the proper fabric.

| Function | GI Flashing | Aluminum Flashing | P.C Flashing |

|---|

| Power | High | Medium | Low |

| Rust Resistance | True | Awesome | High Quality |

| Price | Less Costly | Better | Low |

| Lifespan | Lengthy | Lengthy | Medium |

| Great Use | Roofs & walls | Coastal areas | Light use |

G.I flashing is a balanced choice in phrases of power, charge, and sturdiness.

G.I Flashing Set up: Step-by-Step Manual

Right installation is key to preventing leaks. Beneath is a simple clarification of the procedure.

Tools Required

- Measuring tape

- Tin snips or metallic cutter

- Hammer or drill

- Roofing nails or screws

- Sealant

Step 1: Measure the Place

Degree the duration and width wherein flashing is wanted.

Step 2: Cut the GI Sheet

Reduce the flashing sheet or roll in line with measurements.

Step 3: Bend the Flashing

Use gear to bend the sheet so it suits snugly into corners or joints.

Step 4: Restoration the Flashing

Comfortable with the usage of nails or screws at proper intervals.

Step 5: Seal the Edges

Follow water-resistant sealant to save you water entry.

Following these steps ensures a long-lasting and leak-evidence set up.

G.I Flashing for Roof Protection

Roof flashing is one of the maximum critical uses of galvanized iron sheets. Roofs are continuously exposed to rain, sun, and wind.

Why Roof Flashing Topics

- Prevents water from coming into roof joints

- Protects timber structures under

- Reduces upkeep costs

A properly hooked up flashing machine can make bigger roof existence via many years.

Shopping for G.I Flashing: What to Check

- Before buying, don’t forget these elements:

- Zinc coating first-class

- Thickness of the sheet

- Length necessities

- Supplier recognition

- Warranty (if available)

Many house owners prefer shopping for G.I flashing from reliable providers or shops like huge hardware chains, consisting of G.I flashing alternatives to be had at domestic improvement outlets.

Renovation Tips for G.I Flashing

Although G.I flashing is durable, normal inspection helps amplify its lifestyles.

Upkeep Checklist

- Check for rust spots

- Investigate sealant situation

- Replace unfastened nails or screws

- Easy particles around flashing

Annual inspection is common enough for residential buildings.

Not Unusual Mistakes to Avoid

- The use of very thin sheets in heavy rainfall areas

- Negative sealing at joints

- Incorrect bending angles

- Blending incompatible substances

Averting these mistakes can prevent leaks and harm.

FAQs

What’s G.I flashing used for?

It’s far used to guard roofs, walls, and joints from water leakage.

Is G.I flashing higher than aluminum?

GI flashing is stronger and more inexpensive, while aluminum gives better corrosion resistance in coastal regions.

How lengthy does G.I flashing final?

With right set up and maintenance, it may last 15–25 years.

Can G.I flashing be used for homes?

Yes, it is normally utilized in residential production.

What thickness is first-rate for roof flashing?

For homes, 0.40 mm thickness is generally advocated.

Can G.I flashing rust?

The zinc coating protects it, however harm to the coating can cause rust over the years.

Conclusion

G.I flashing is a simple but effective solution for defensive homes from water harm. Its strength, affordability, and simplicity of installation make it a famous choice for roof flashing and wall joints. By choosing the right size, thickness, and set up technique, homeowners can drastically grow the lifespan in their roofs and systems.

Whether you are planning a new creation or repairing an existing building, making an investment in high-quality galvanized flashing is a clever and long-term choice.